so in the 'post your builds' thread, there is a ton of good information, questions and answers on everything from basic, to highly advanced builds and techniques. its quickly grown into an amazing resource, but its also quickly grown too large to find that info in. most of us have answered the same questions over and over again.

the idea for these 'the official x thread', is to get the information on 'x' (build/technique) all in one place so its easier to find, and consolidate the questions/answers/discussion a little bit, and leave that other thread for pics, chat and encouragement. links to all the 'official' threads are collected here, have a look through the rest for tips on everything from planning a build in steam-engine, beginner to advanced builds, and even coil photography. feel free to share tips, ask questions and discuss staple coils and all their variants in here...

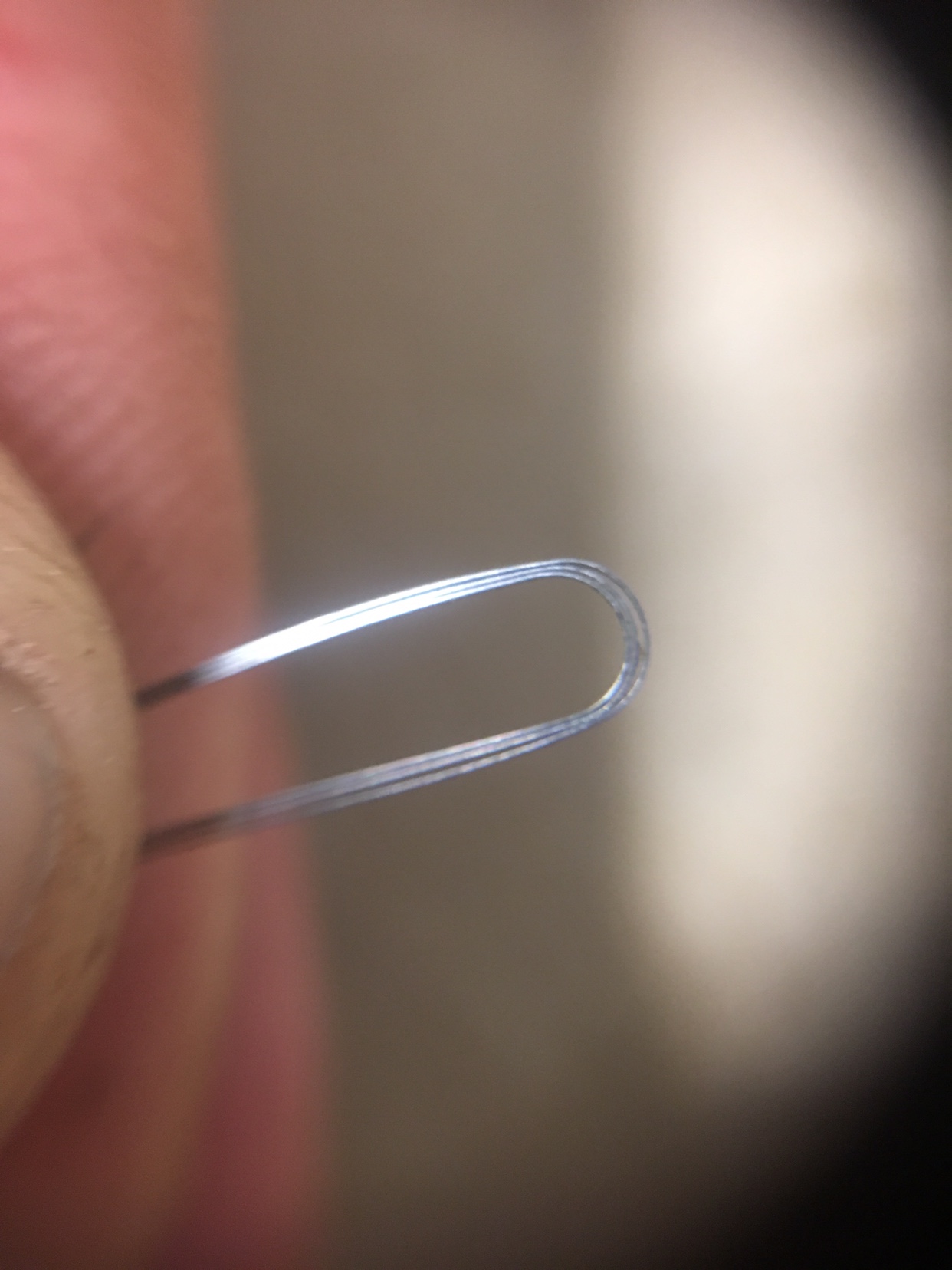

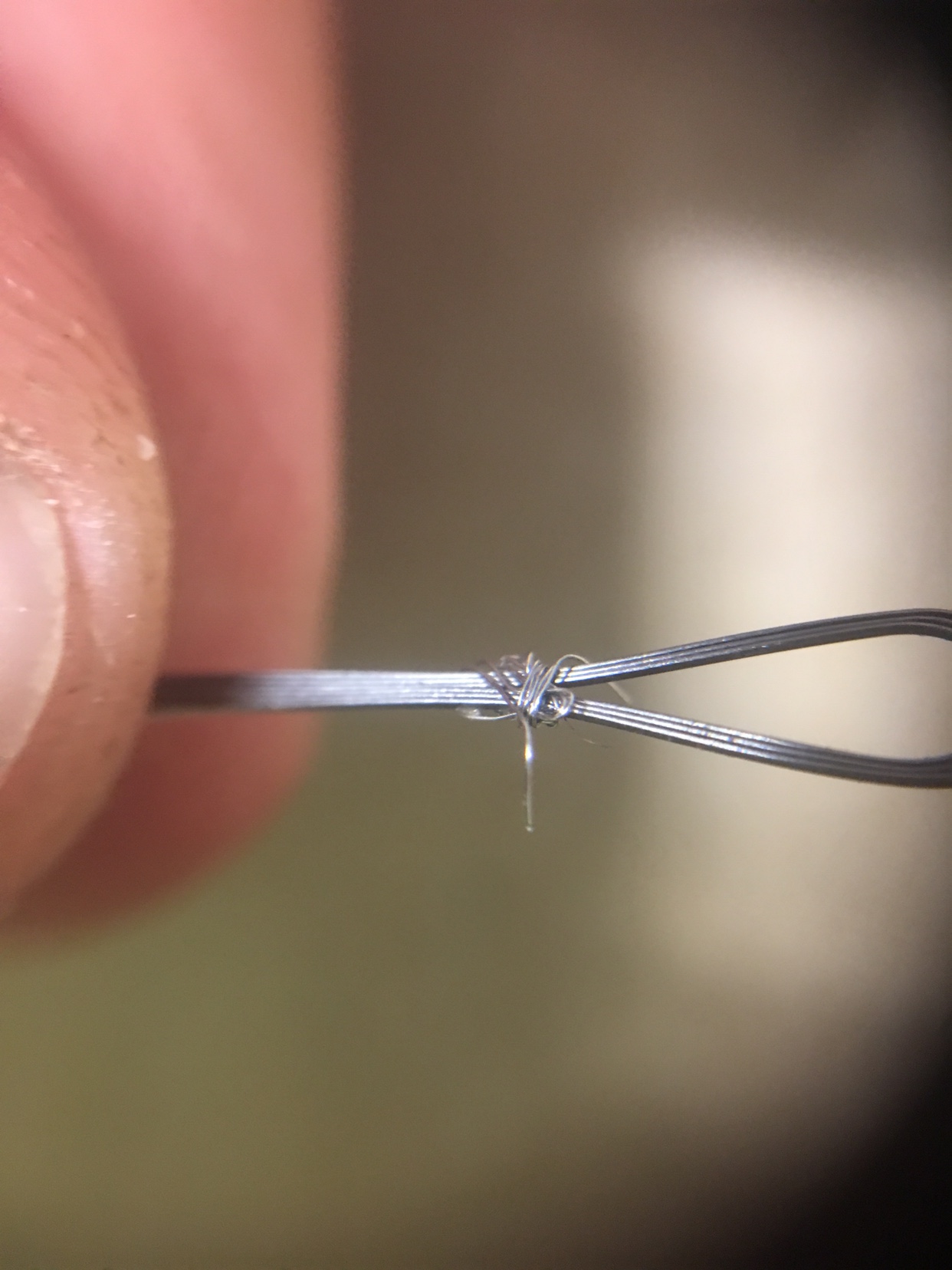

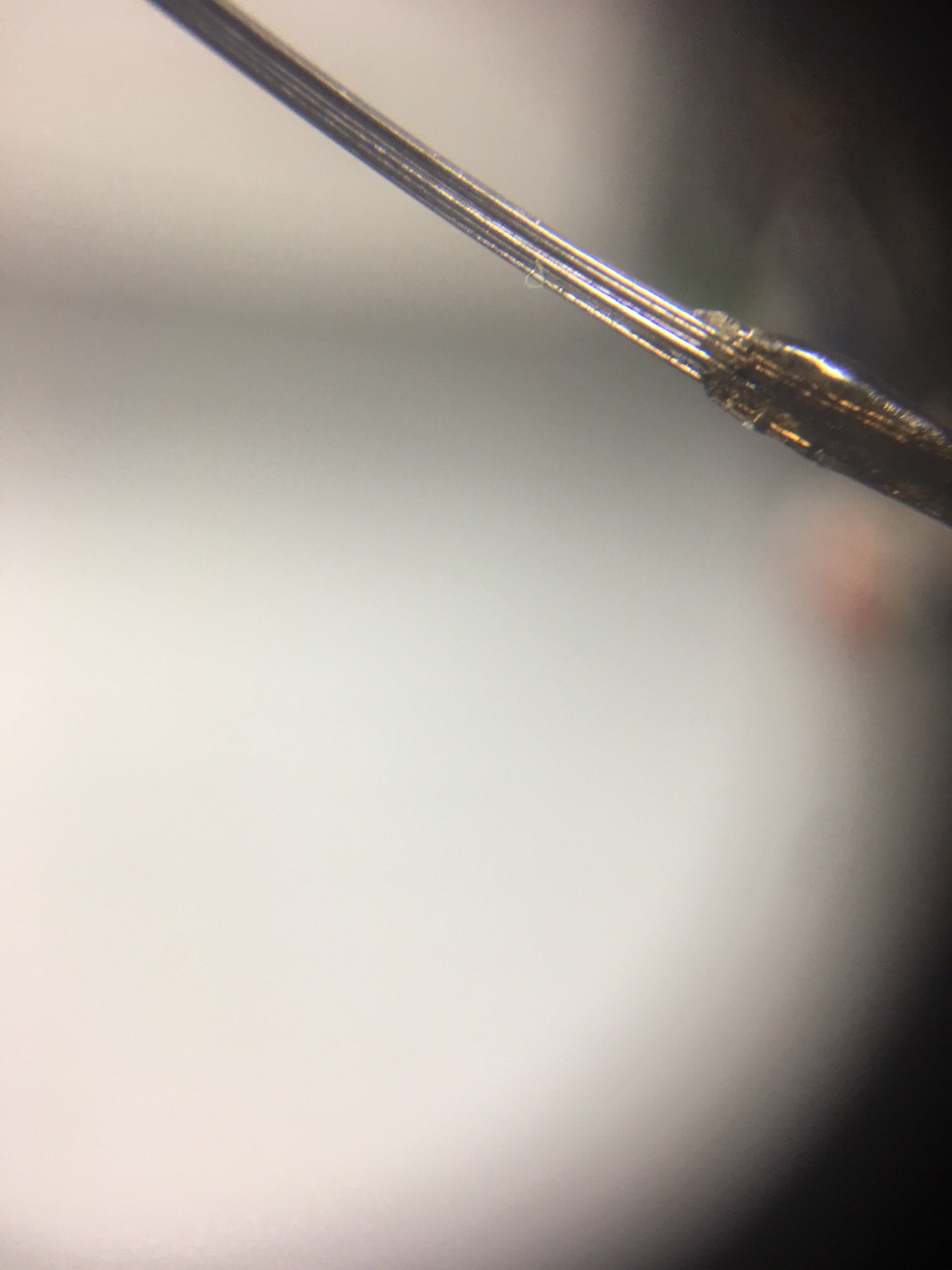

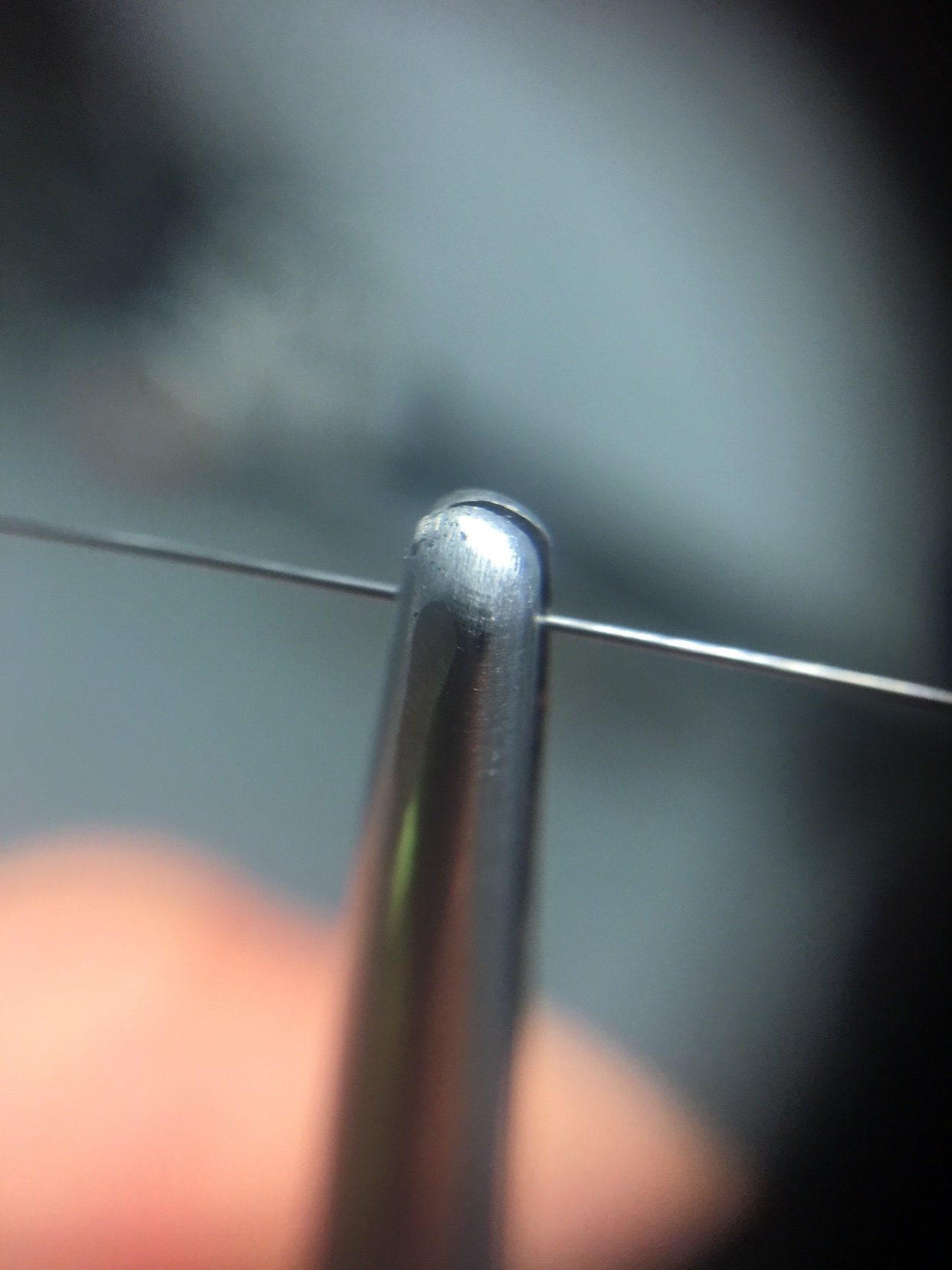

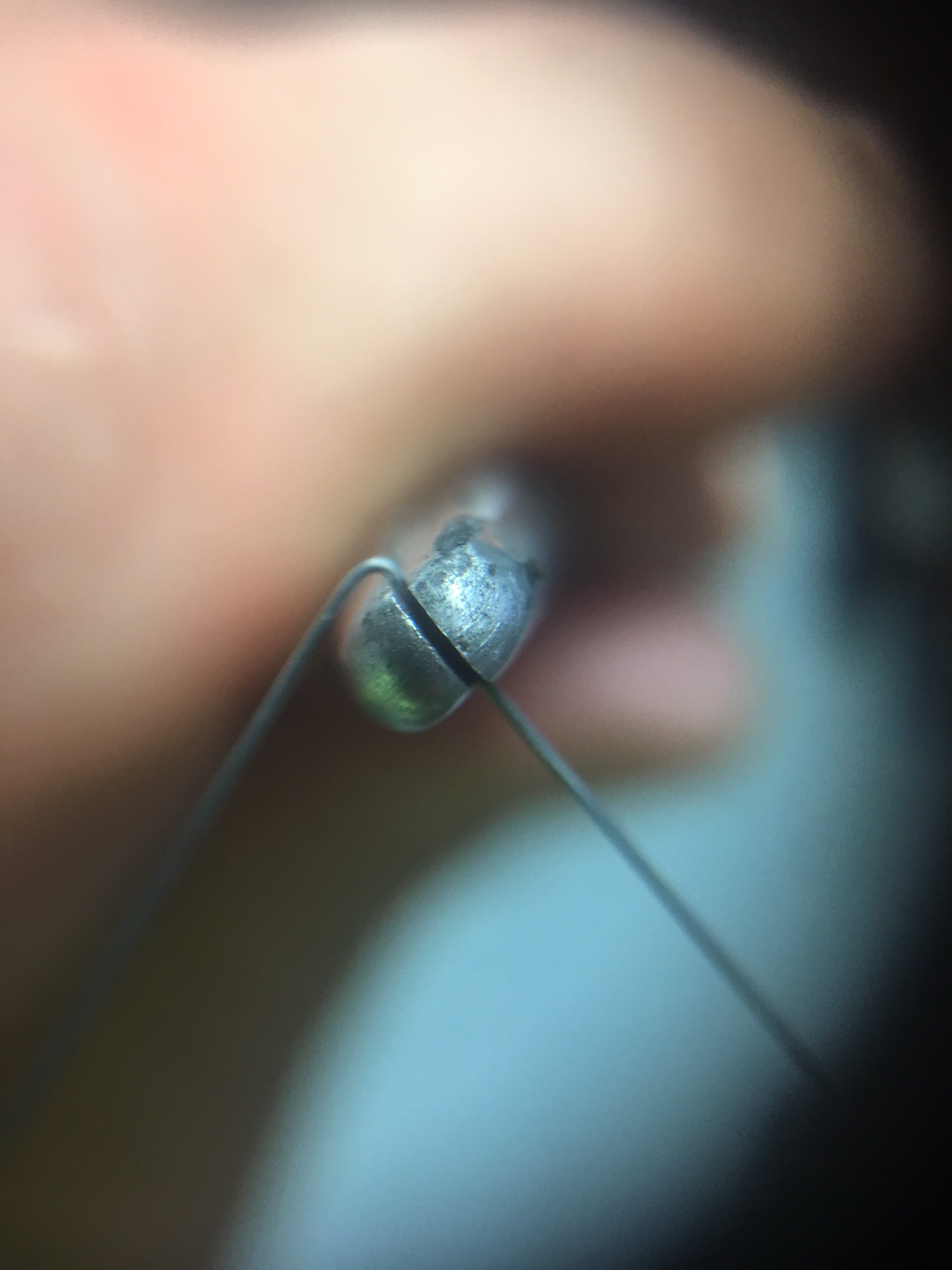

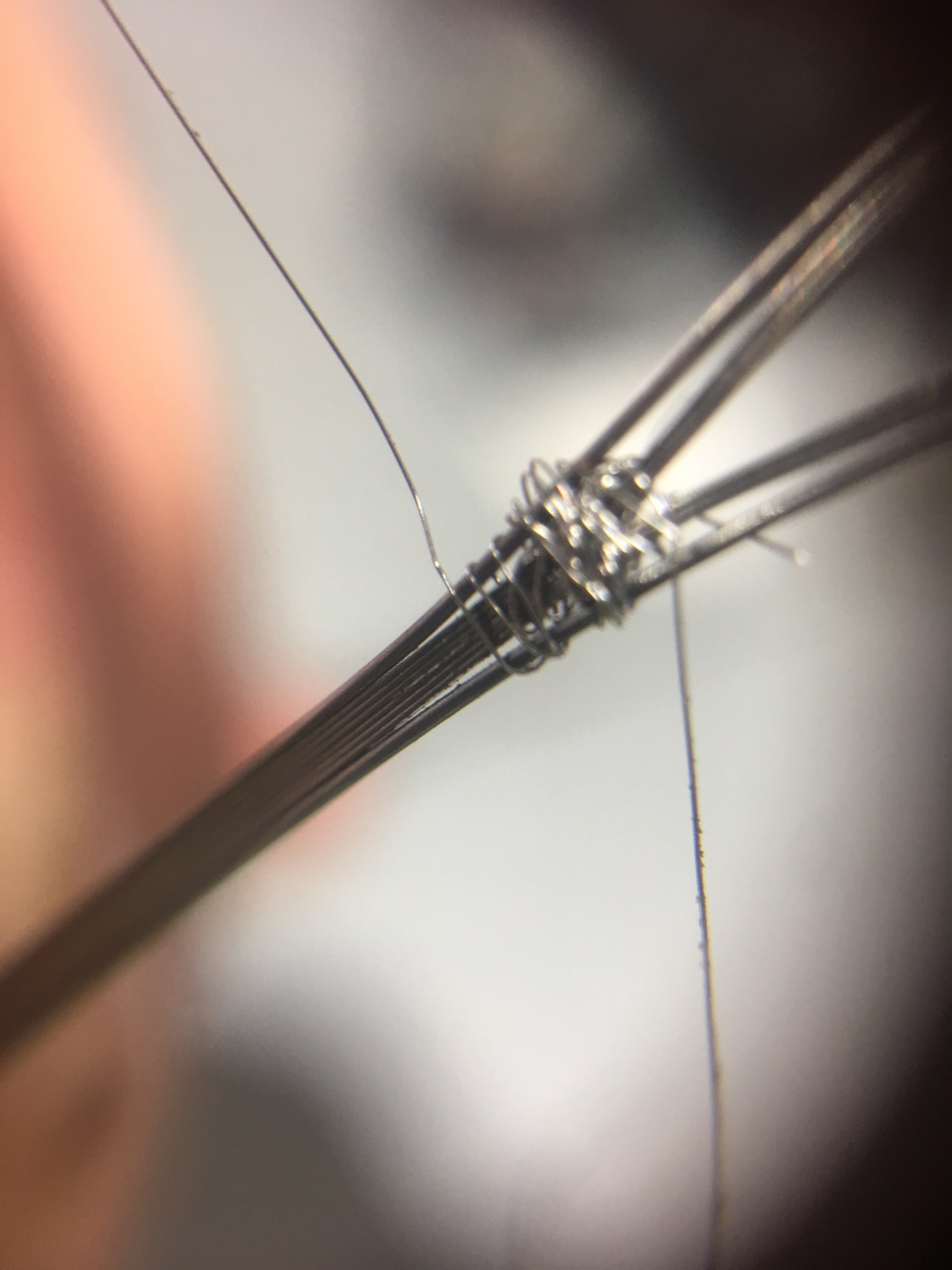

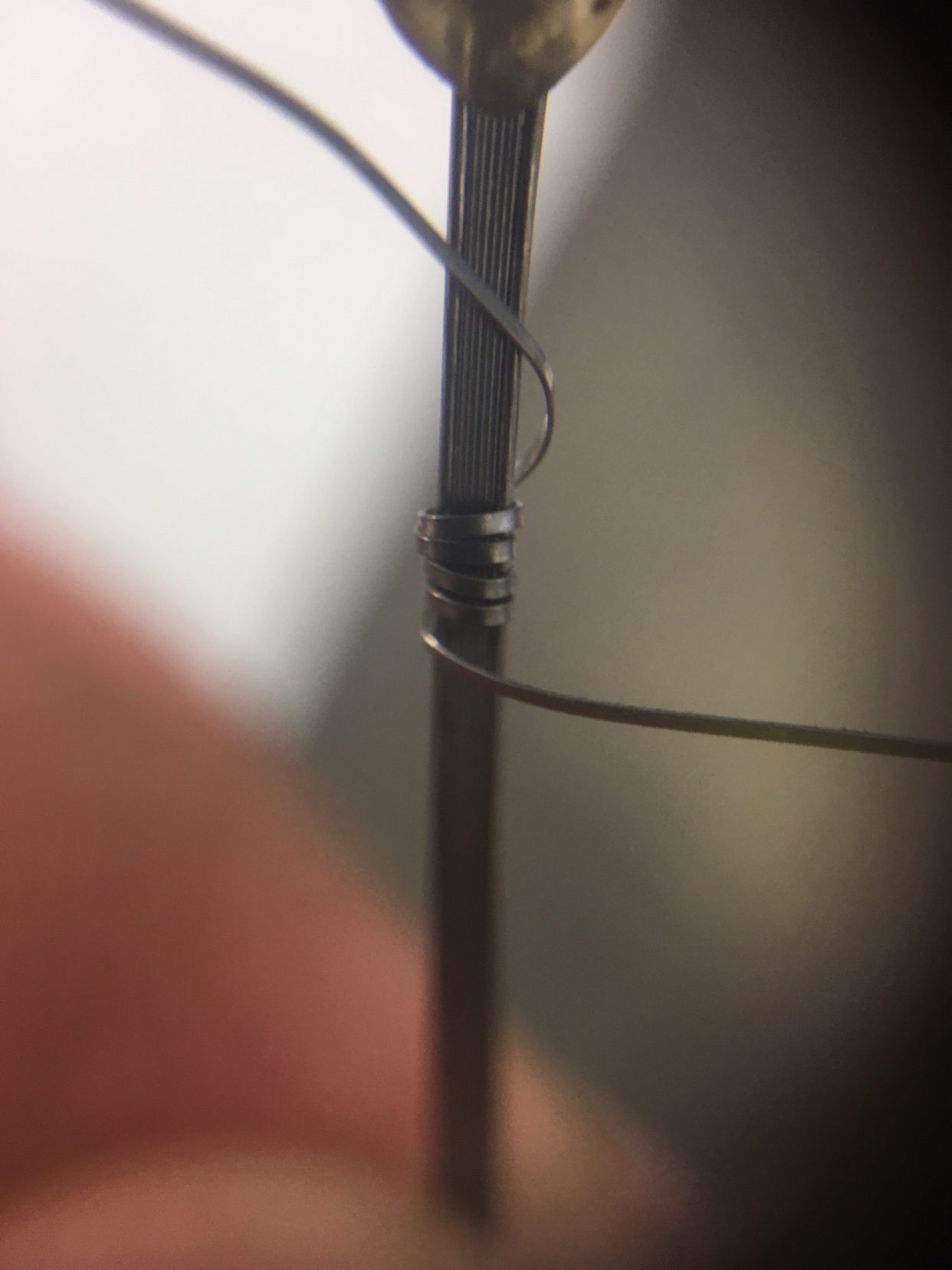

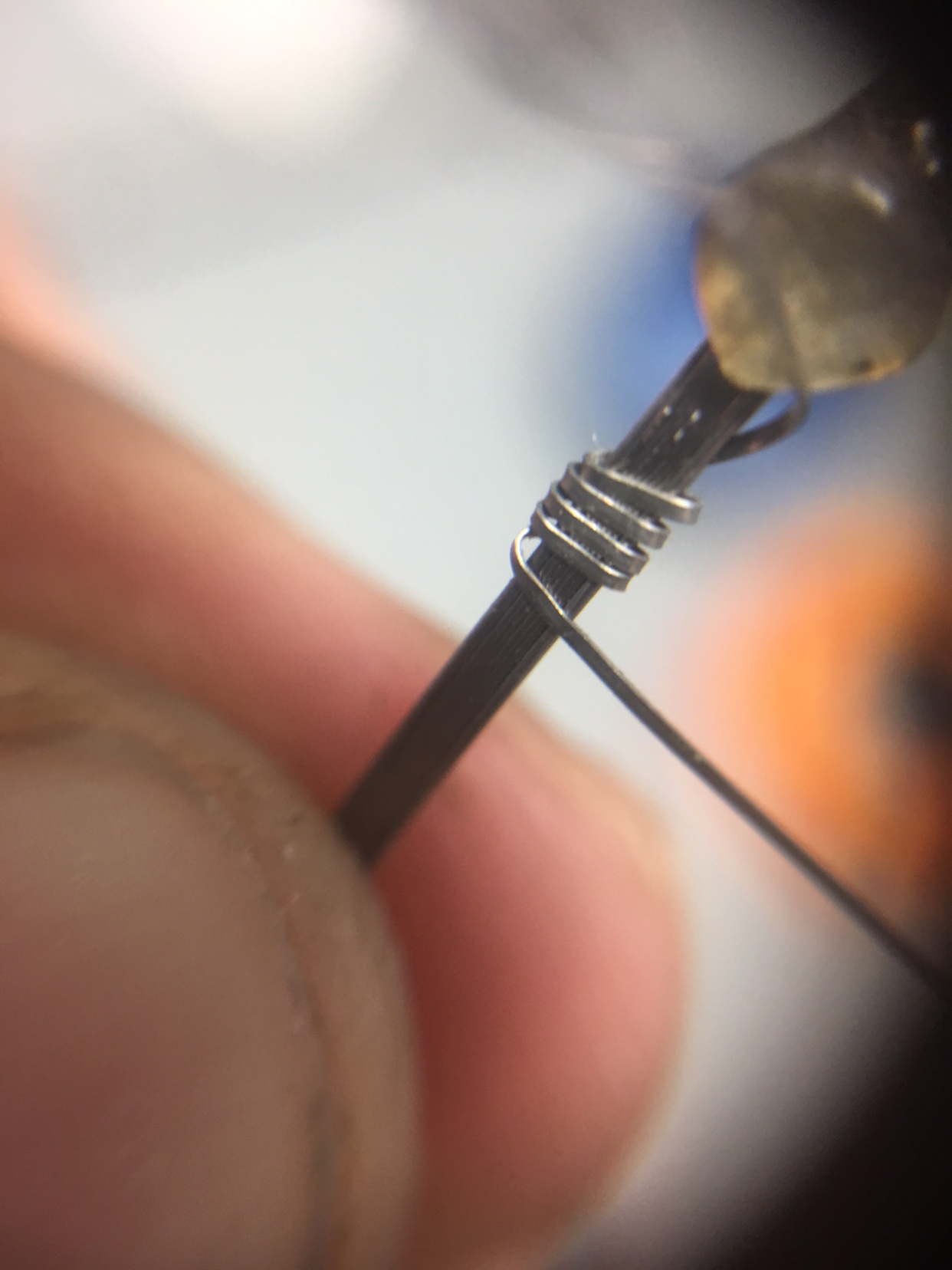

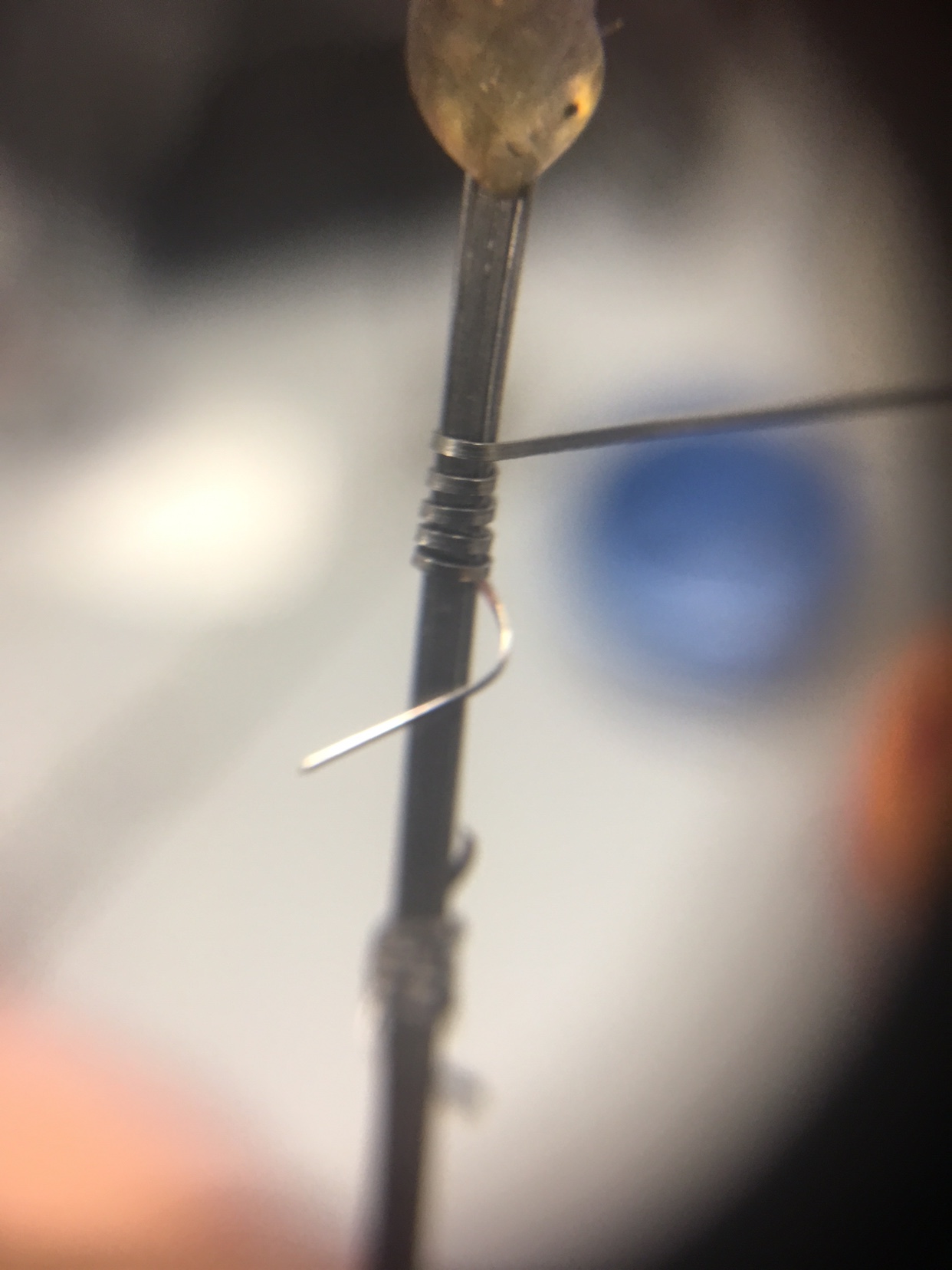

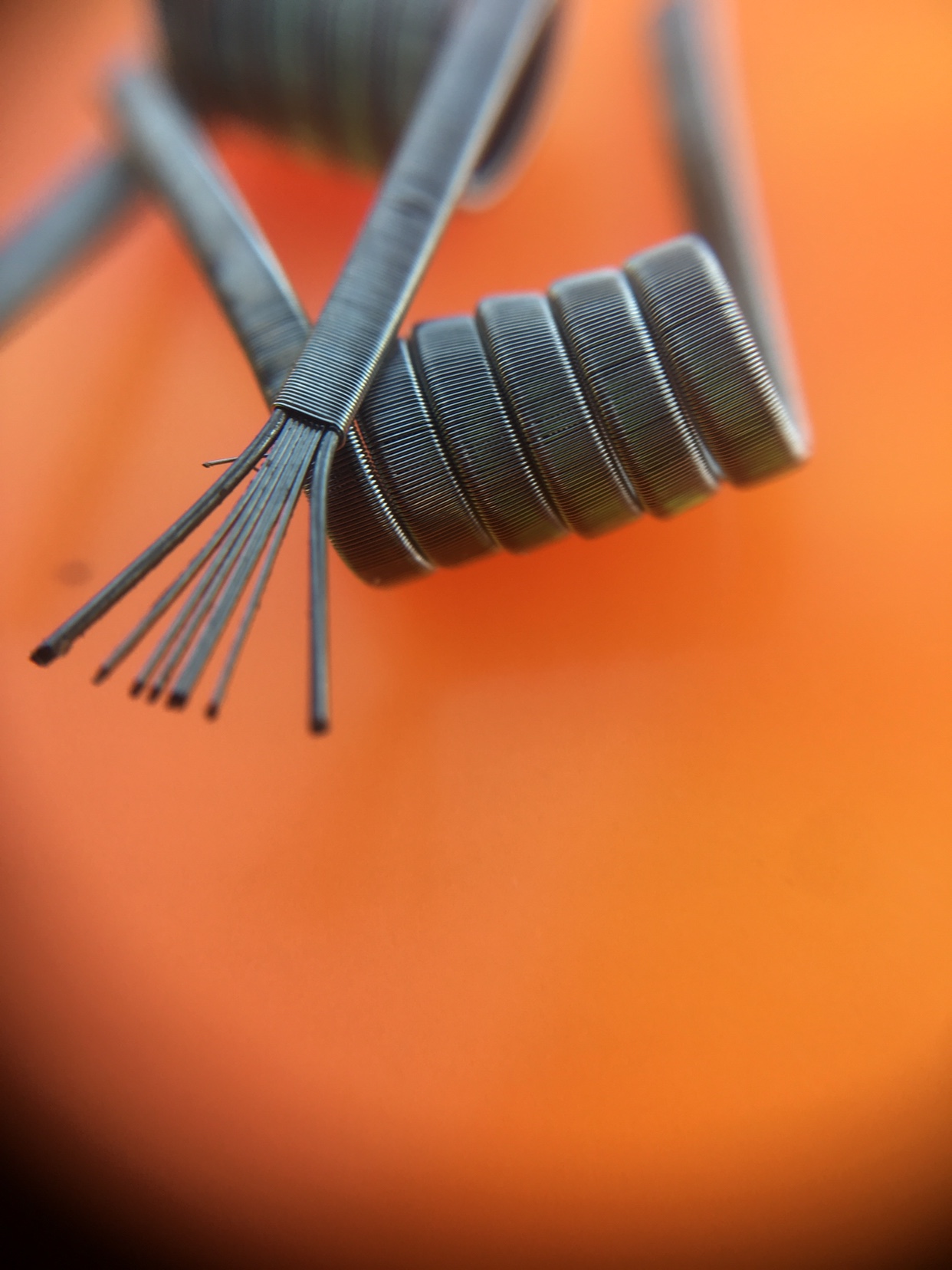

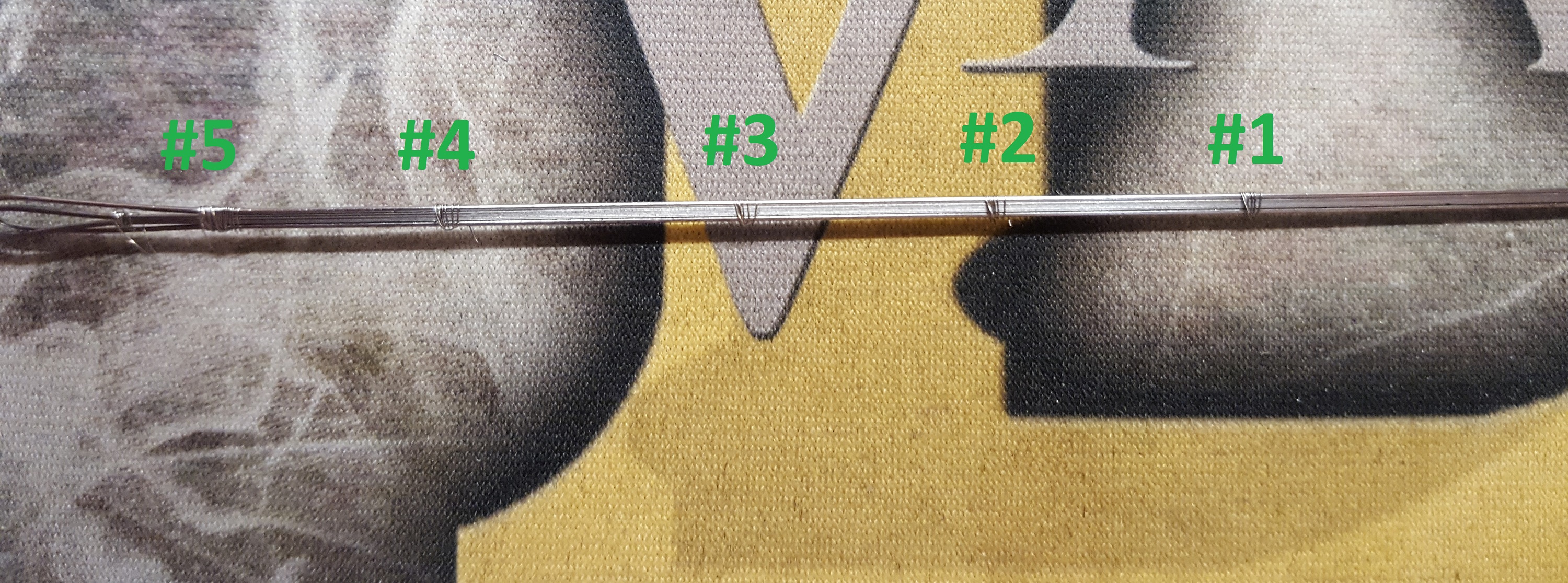

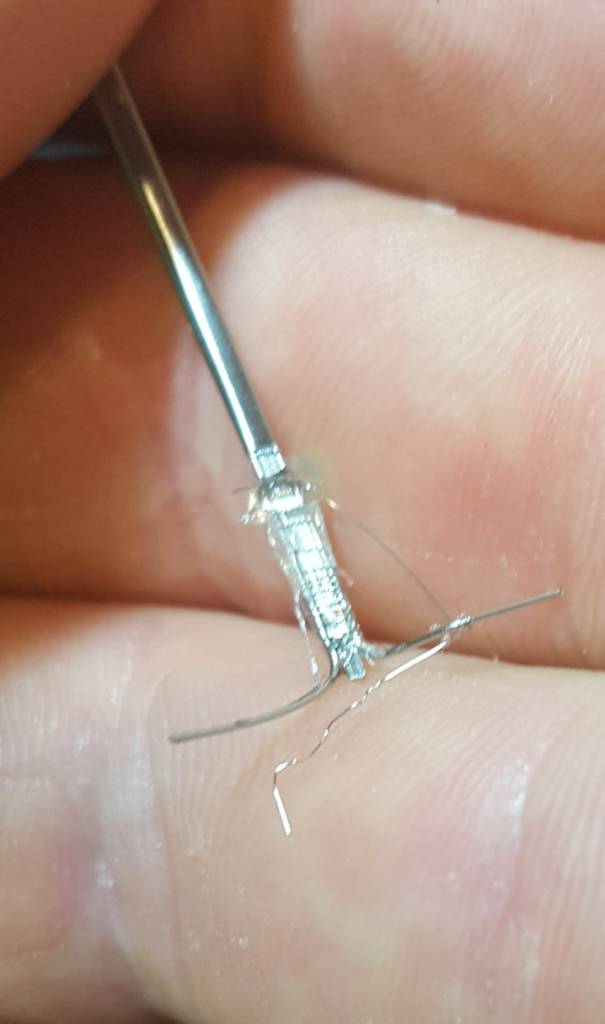

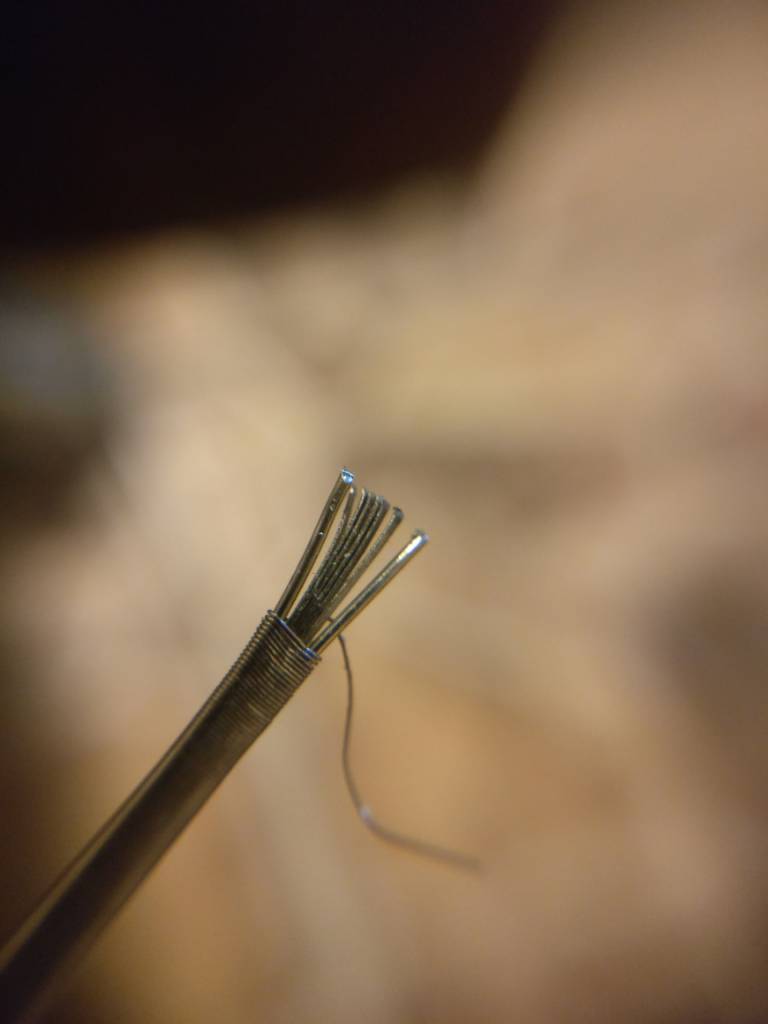

coil info: a default staple coil is made from stacked ribbon wire, which is then clapton wrapped.

there are a lot of variants of this coil, including framed staples, alien staples, alien framed staples, stapled stagger fused claptons, stapled staggertons and many more. stacked ribbon wire is an ingredient in just about everything, so i consider it to be one of the fundamental techniques to learn for anyone.

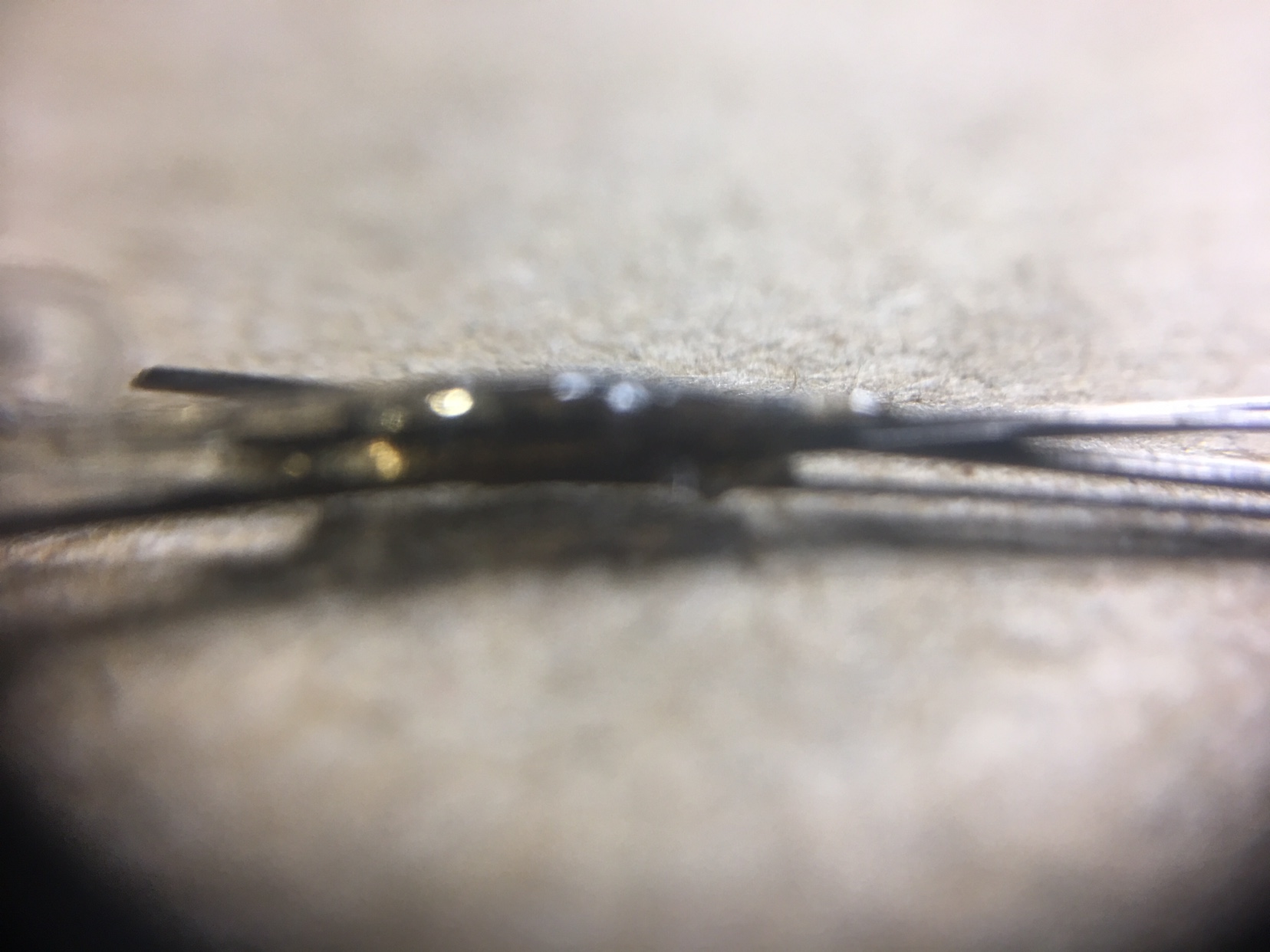

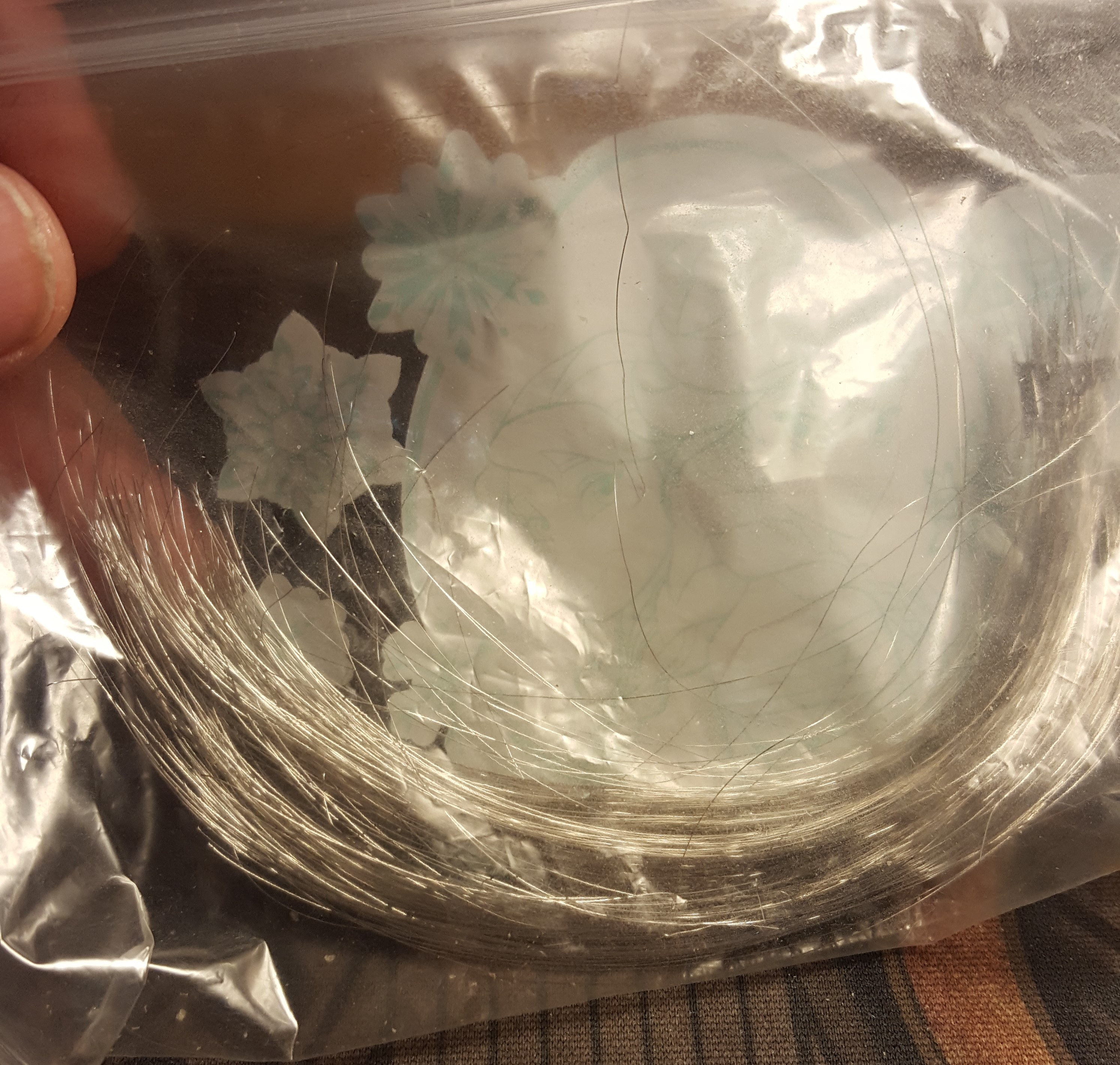

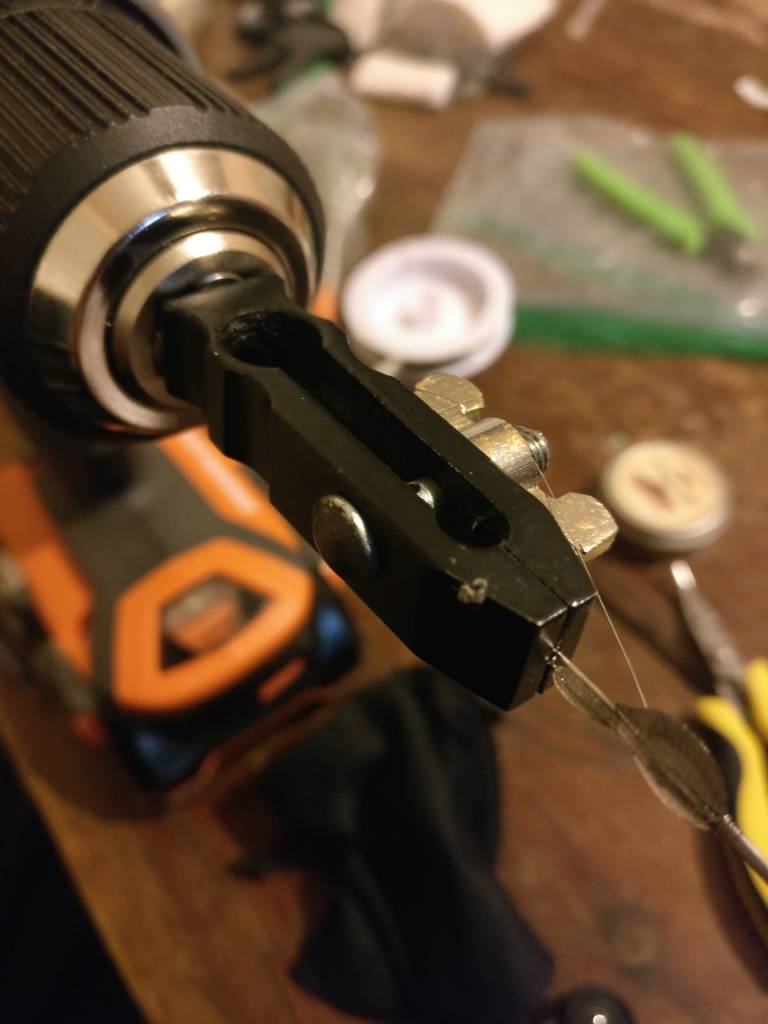

tip: stacking ribbon is fucking hard sometimes. its almost impossible to recover from a kink or any imperfection. good practice is to stretch each measure of it as you are taking it off the spool. what i do is grab the end of the wire with pliers and pull the length i need off the spool, then i grab the spool tight and pull the pliers until the wire gives a little tiny bit. usually thats enough to force it straight so i can cut it off the spool and lay it out of the way while i do the rest. if they are curling up on you at all, they will be very hard to work with.

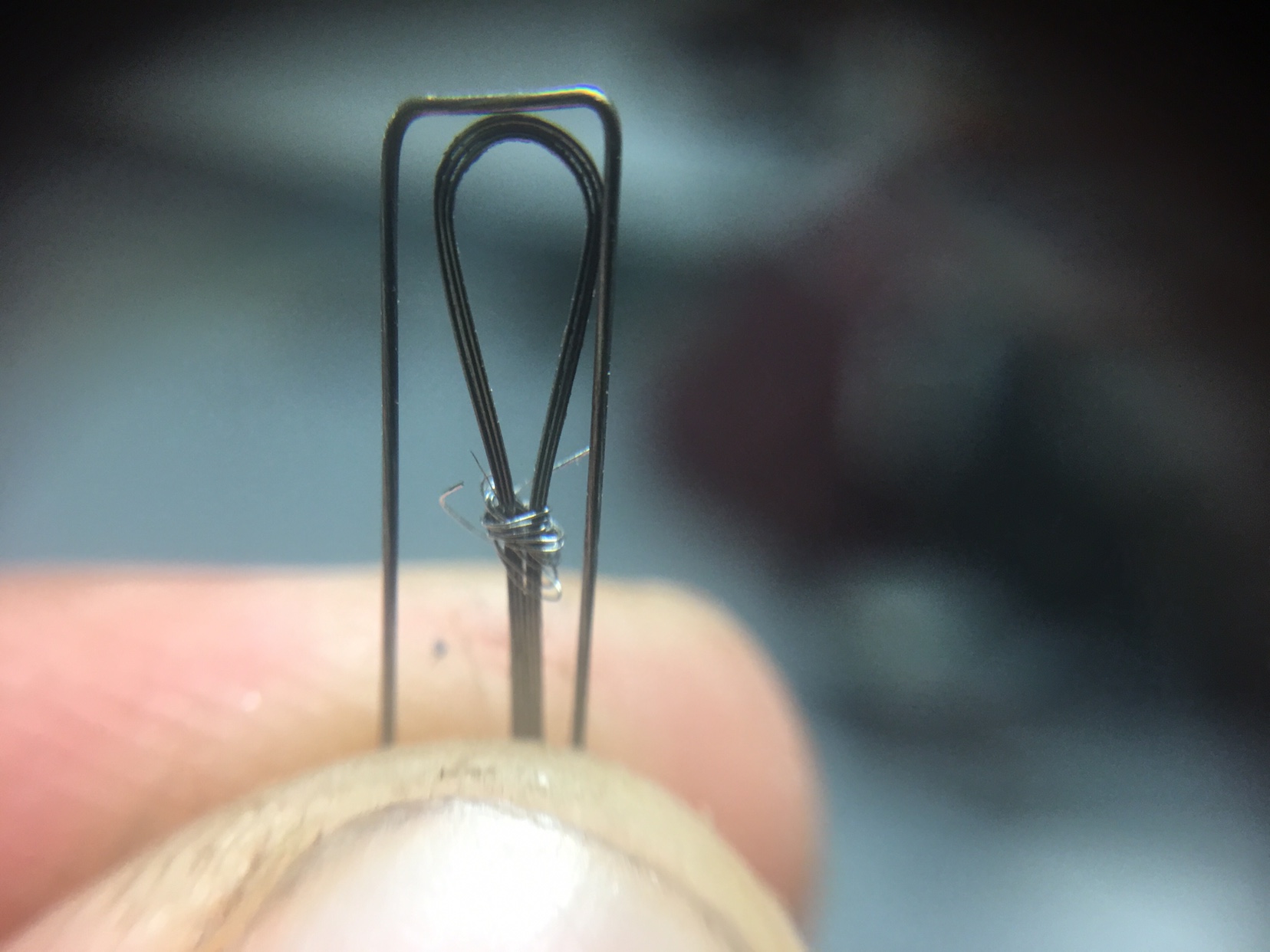

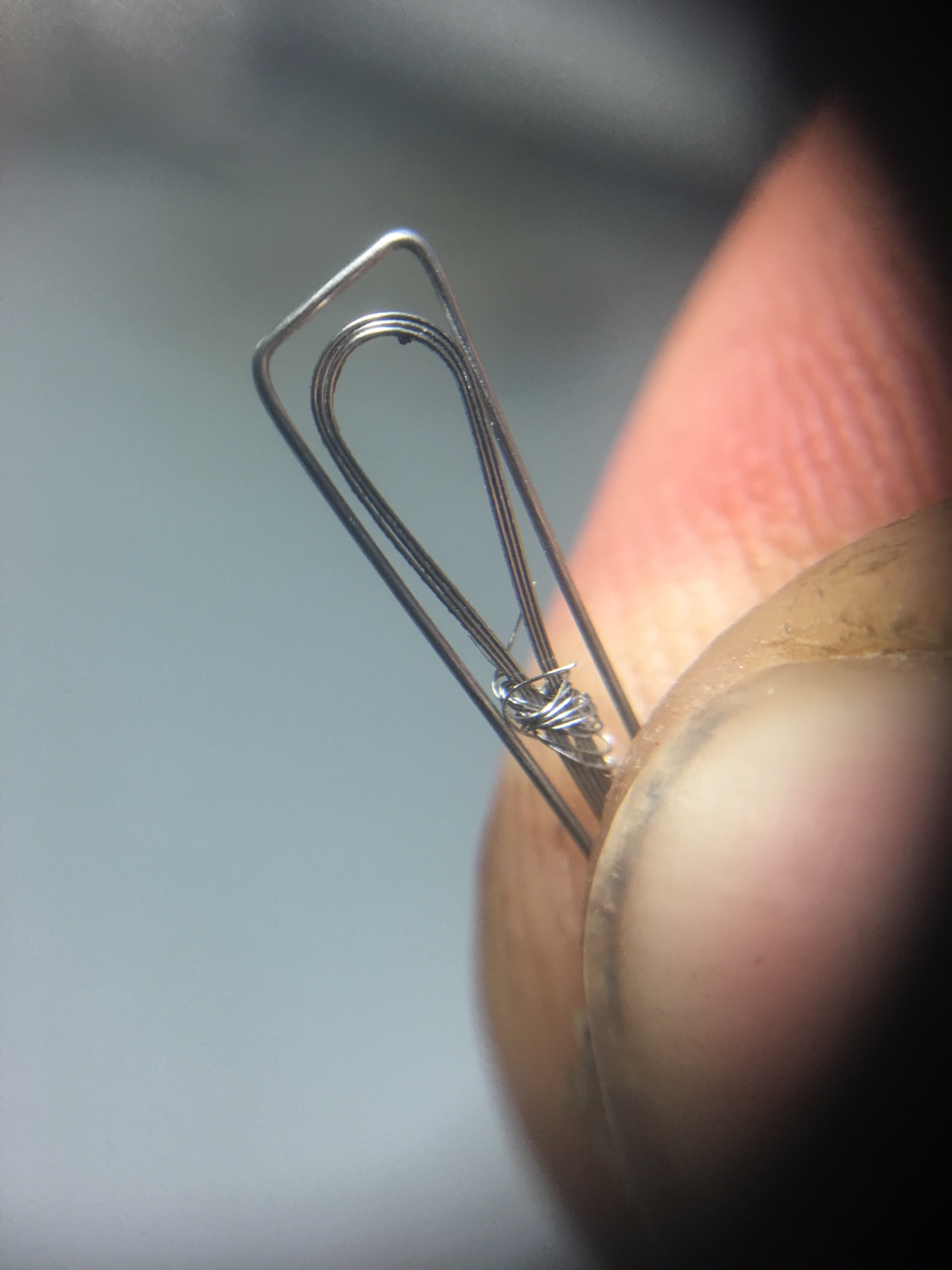

tip: i cut off 2x the length of wire i need and fold it in half. that makes the folded end of the stack more solid and gives me a bit less to worry about when im in the first couple steps of making a stack for something.

pic: framed staple in petri rda

vid:heres a classic tutorial for the staple coil

the idea for these 'the official x thread', is to get the information on 'x' (build/technique) all in one place so its easier to find, and consolidate the questions/answers/discussion a little bit, and leave that other thread for pics, chat and encouragement. links to all the 'official' threads are collected here, have a look through the rest for tips on everything from planning a build in steam-engine, beginner to advanced builds, and even coil photography. feel free to share tips, ask questions and discuss staple coils and all their variants in here...

coil info: a default staple coil is made from stacked ribbon wire, which is then clapton wrapped.

there are a lot of variants of this coil, including framed staples, alien staples, alien framed staples, stapled stagger fused claptons, stapled staggertons and many more. stacked ribbon wire is an ingredient in just about everything, so i consider it to be one of the fundamental techniques to learn for anyone.

tip: stacking ribbon is fucking hard sometimes. its almost impossible to recover from a kink or any imperfection. good practice is to stretch each measure of it as you are taking it off the spool. what i do is grab the end of the wire with pliers and pull the length i need off the spool, then i grab the spool tight and pull the pliers until the wire gives a little tiny bit. usually thats enough to force it straight so i can cut it off the spool and lay it out of the way while i do the rest. if they are curling up on you at all, they will be very hard to work with.

tip: i cut off 2x the length of wire i need and fold it in half. that makes the folded end of the stack more solid and gives me a bit less to worry about when im in the first couple steps of making a stack for something.

pic: framed staple in petri rda

vid:heres a classic tutorial for the staple coil

Last edited: