stapled helix. a quick rundown of the process:

-figure out how much coil you need to make (i use

wire wizard)

-make an inch or two more than double that amount of twisted frame wire

-the twist pitch determines the angle of the helix wraps, so keep that in mind and pay attention so you dont miss your traget

-make a ribbon stack

-fold the twisted frames over the stack and fasten it together using your preferred method

-wrap your fuse wire into the grooves on the frames, but to get the fuse to follow the twist pitch, you might find that your wraps are 6 or 7 twists apart

-figure that number out in the first inch or so, then unwrap it and start again

-this time, count the twists between each wrap on each side/frame of the wire so you end up with one wire wrapped every x twists (x = however many looks good to you)

---i watched a video where the guy said not to use a drill/hand drill, just fasten it into a vise and use a pre-cut length of wire to go over-under until its done

---i used a hand drill and a spool like i was claptoning, but i turned the hand drill with my fingers, and every time i counted out my twists and put the wire into the groove i pulled it tight before i rolled the chuck over. this pass took about an hour for 12 inches of finished product

---the second pass is much faster because you dont have to count, you have a visual guide. i used the crank on the drill and got into a pattern of weaving back and forth into the correct grooves. these passes took a few minutes each (5 total for me, before i ran out of wrap one what would have been my 6th/final pass)

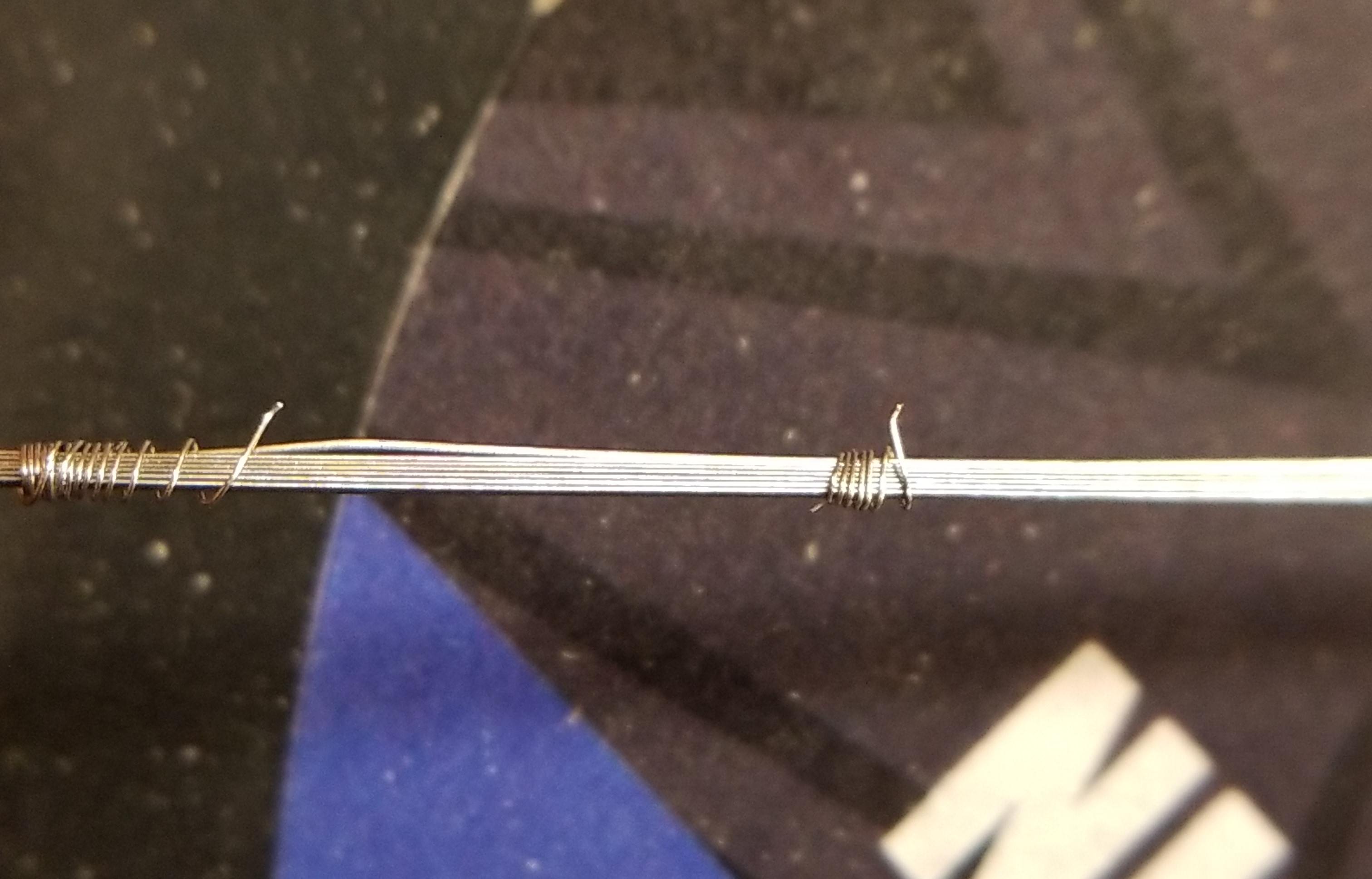

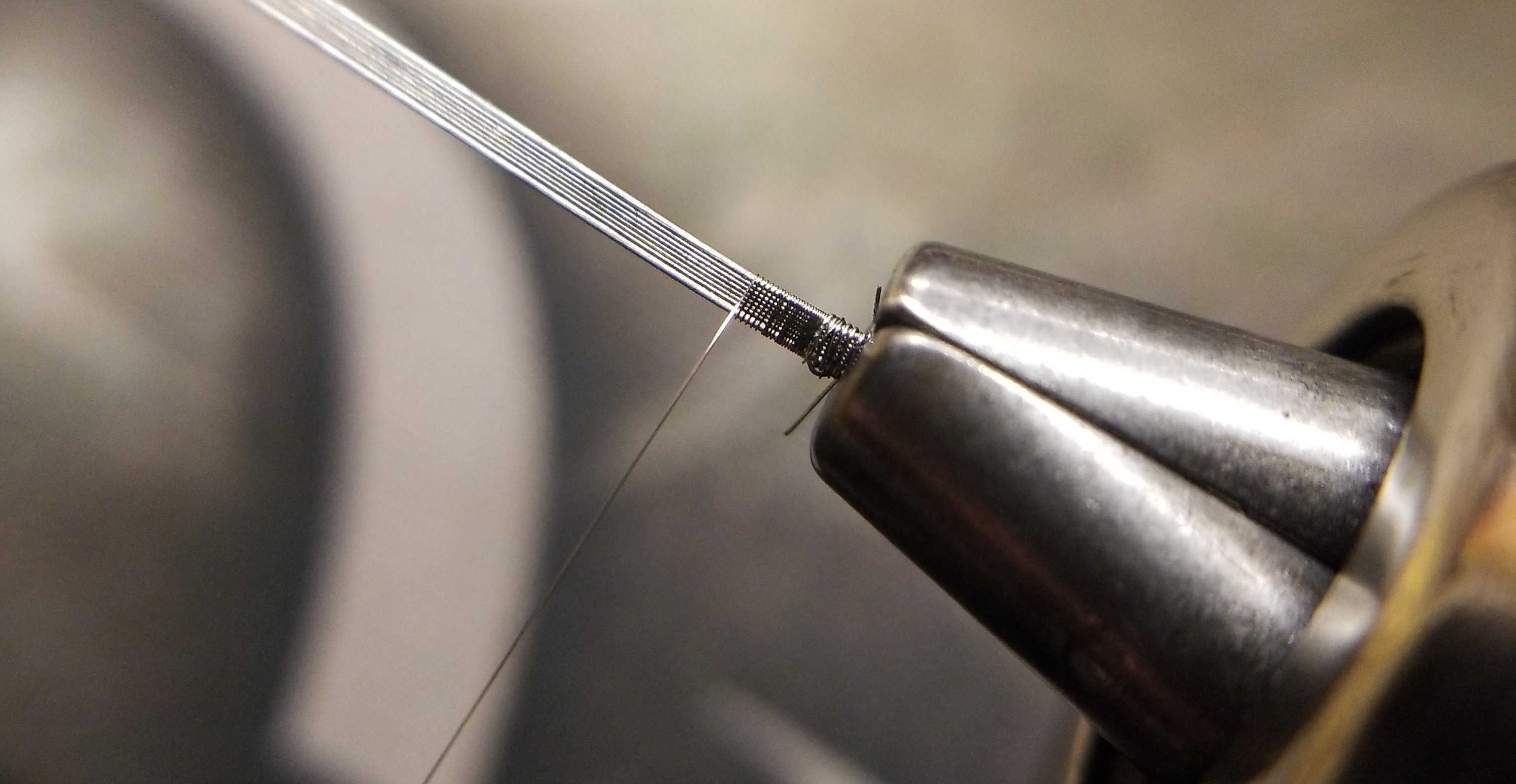

the drill side of my setup. i am using a chucky clamp from usaohmmeters. you can see each pass of fuse wire wrapped around the screw and starting out, and my glue dab. stuck in the chucky clamp is the loop end of my ribbon stack and frames:

View attachment 100490

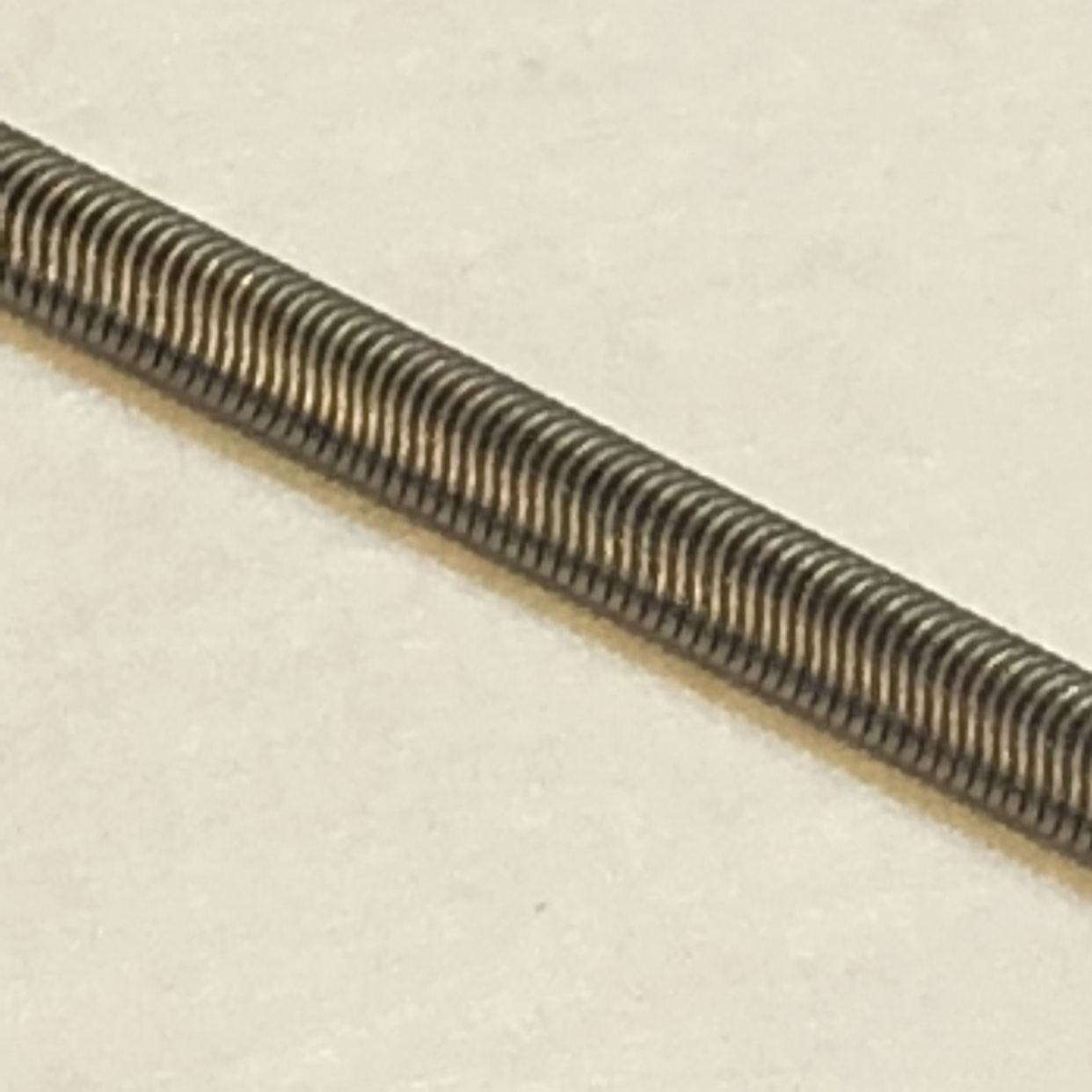

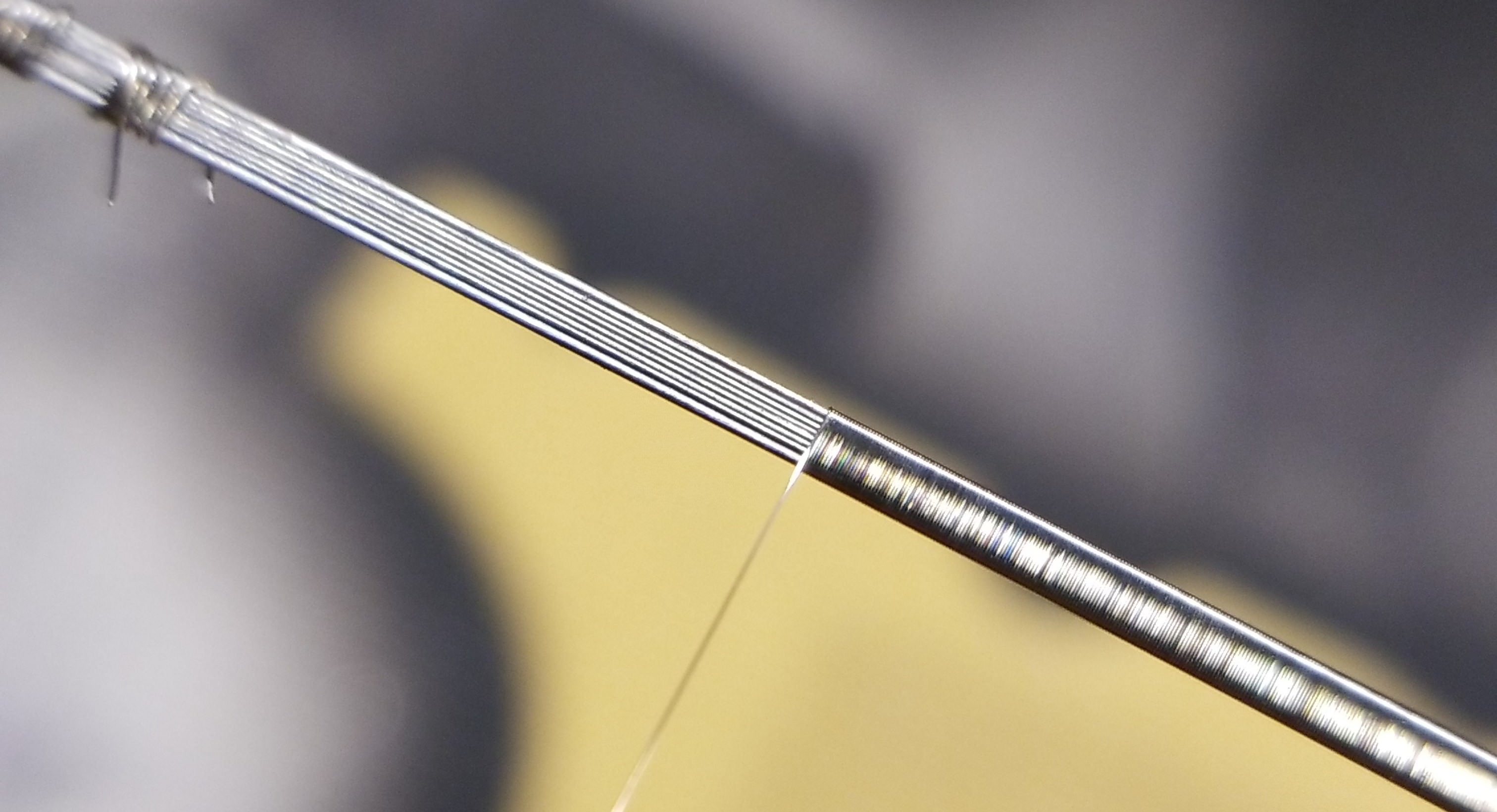

a wire shot:

View attachment 100491

im using a spinLT with a swivel clamp that works just like the chucky. when i finished each pass, i held the fuse against the glue dab and touched it with a lighter so it would stick in tight. usually i would float the ribbon stack by making the frames longer than it and only attach them to the swivels, but i fucked up this time and did it backwards. it didnt make any difference because i was turning the drill a half turn at a time so there was no twist being applied to my cores. when i got near the end of the first pass there was a bit of a bulge in my ribbon stack, and my frames were still loose, so i hit the glue a little with the lighter and released the bulge and caught my frames in the glue while it was hot.

View attachment 100492

View attachment 100493

).

).