I was thinking about this last night, but without a wired pedal -

--Drill upside down in a vise

--Small rope or any cording that doesn't stretch

--spray rubber on the part of the rope that touches the trigger for grippiness

--two clamps with a dowel and short PVC pipe to spin freely, as a pulley for the rope --this part would take the most troubleshooting

--measure rope to come just above the floor after tying into a loop

--wooden block for a pedal, either glue or cut a groove into the pedal to hold the rope in place - could attach the block to something heavy with grip on the bottom to secure it in place better

If the dowel/pulley is at the correct height, say just below level with the drill trigger, and the rope goes around and back toward the user, seems like it could work

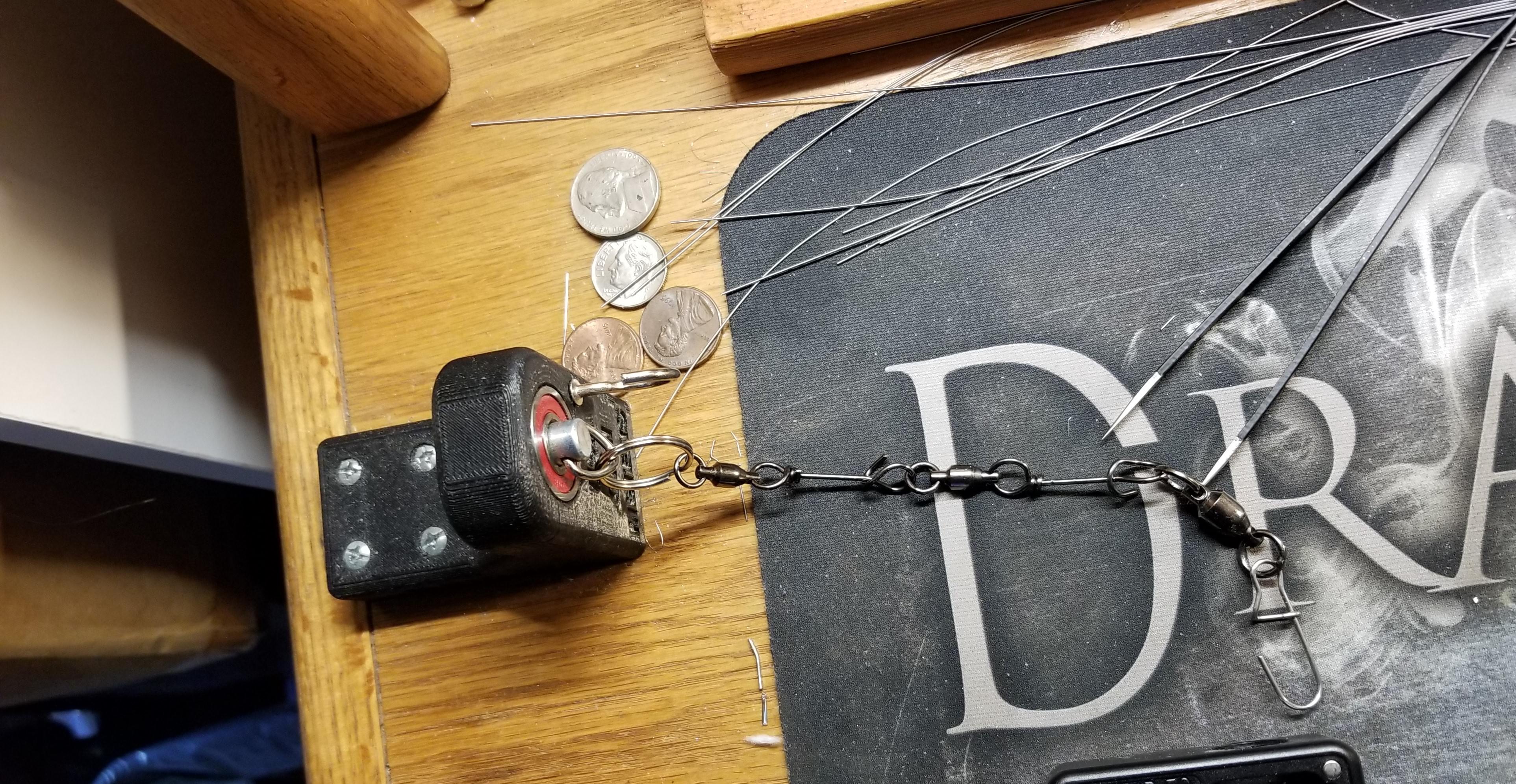

For crazychef's need of moving the drill, a drill press vise could be moved, but I was thinking easier to move the clamp holding the swivels closer or farther as needed

I definitely wouldn't mind one if it came 6 ft long and able to slide the swivel setup back and forth to do longer and shorter decores

I definitely wouldn't mind one if it came 6 ft long and able to slide the swivel setup back and forth to do longer and shorter decores  proper tidy

proper tidy

im interested to see this develop. not sure if i need one, but it could easily become something that changes my mind on that by the time its done.

im interested to see this develop. not sure if i need one, but it could easily become something that changes my mind on that by the time its done.