Not everyone has one. plus, I can clapton a dual core clapton freehand, faster than you can load the wire into that rig.

So? I don't own a Daedalus myself. I'm just pointing out there is no real reason to make simple clapton coils... everyone can use a fused clapton build instead because it's just as easy to make, and it performs a LOT better.

What I have been trying to explain, is the stainless steel wrap heats the juice trapped in the spaces faster than just the core wire. In effect, it increases the entire heating area of the coil. Your NiChrome wraps do exactly the same thing, only slower.

What I've been trying to explain is that the hard scientific truth is you've simply got that backwards. You want the heat to transfer primarily into the juice, NOT the part of the wrap wire that is located at the farthest distance away from the area where most of the juice is located. SS316L wrap wire conducts heat

AWAY from the juice faster, and, in addition, requires more transferred heat ( =transferred energy, expressed in watts, or Joules per second) to give the same temperature increase. Heat is not the same thing as temperature. Again, please read up on

specific heat and

volumetric heat capacity before bothering me with your nonsensical anti-scientific replies.

Even with regulated mods, resistance DOES matter. For one, coil size.

I was talking about how fast it heats up on a regulated mod if everything is equal (including watts) excepting only the metal type and the resistance of the coil. Why do you still keep comparing apples and oranges?

2nd.. Mod upper and lower limits.

Please read my post before hitting the reply button. I said "at least if operating within spec", and I was talking about how fast it heats up, NOT the limitations of the mod.

3rd resistance is use to determine wattage by the mods secondary controller. Formula is volts squared divided by resistance = watts. Very handy to know if you are building a SS coil on an rba mini.

What makes you think I don't already know this? After I already explained countless times you need the watts to be equal if you want to do a fair comparison of how fast it heats up, why do you still keep bringing this up?

For example.. calculate.. 21 wraps of 32ga SS on a 2.5mm id core. = 4.731 Ω (coil length is about 1/4 inch aprox for rba mini) VS

7 wraps of triple parallel, 32ga SS, 2.5id core = 0.671 Ω

Also very handy if you are building a cloud build on a large deck. (regulated mod) because you still need your resistance to be within the mods limitations. Resistance ALWAYS matters.

This is exactly the same amount of wire, same number of total coils, yet one will work on a regulated mod, the other will not. (parallel wrapped coil heats better too.. each strand is a unique coil)

You must always factor in resistance when building a coil. That is why steamengine has it as a set value. Try dual coils, 20Ga SS 6 wraps on you regulated mod. It won't work

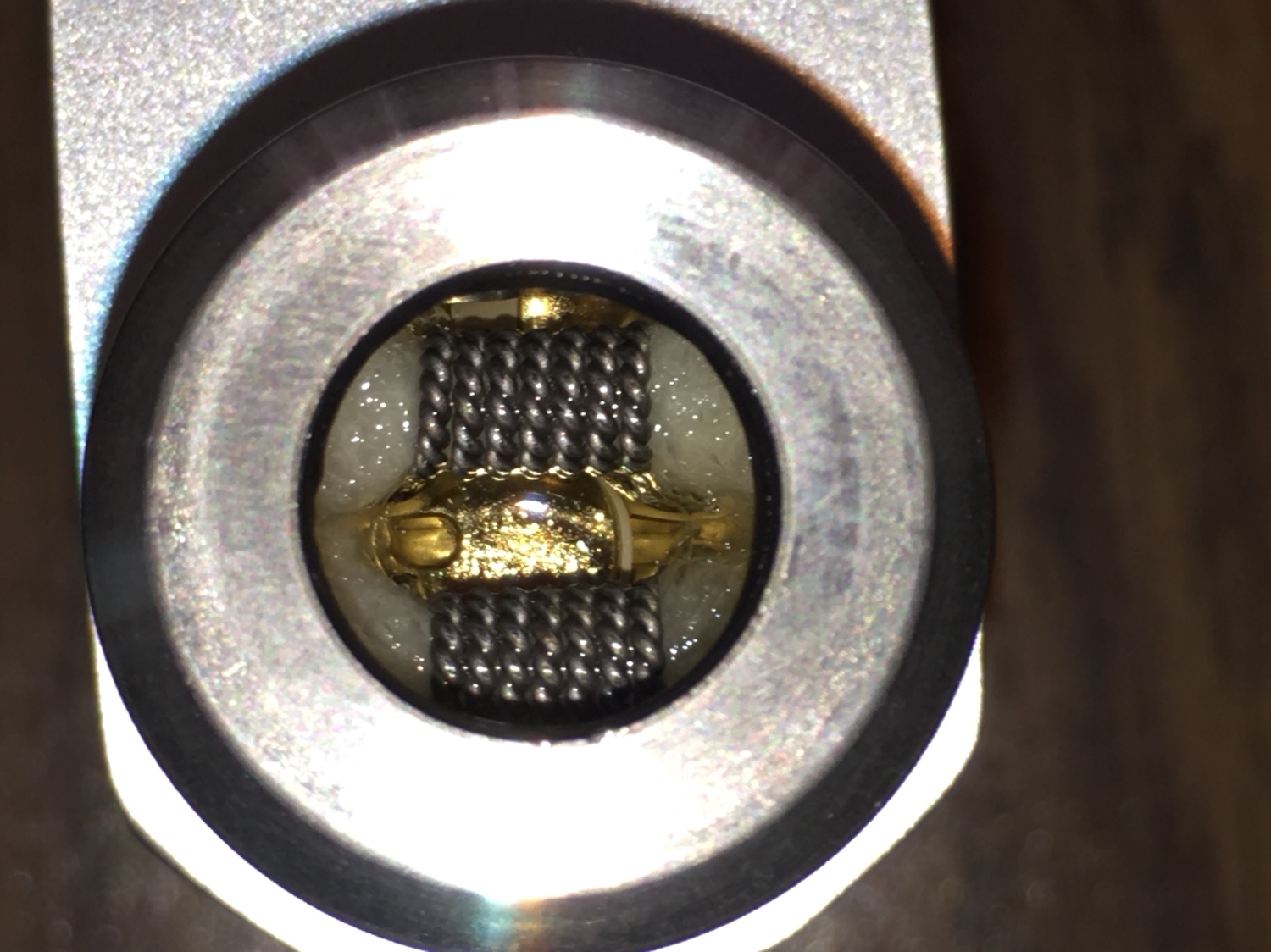

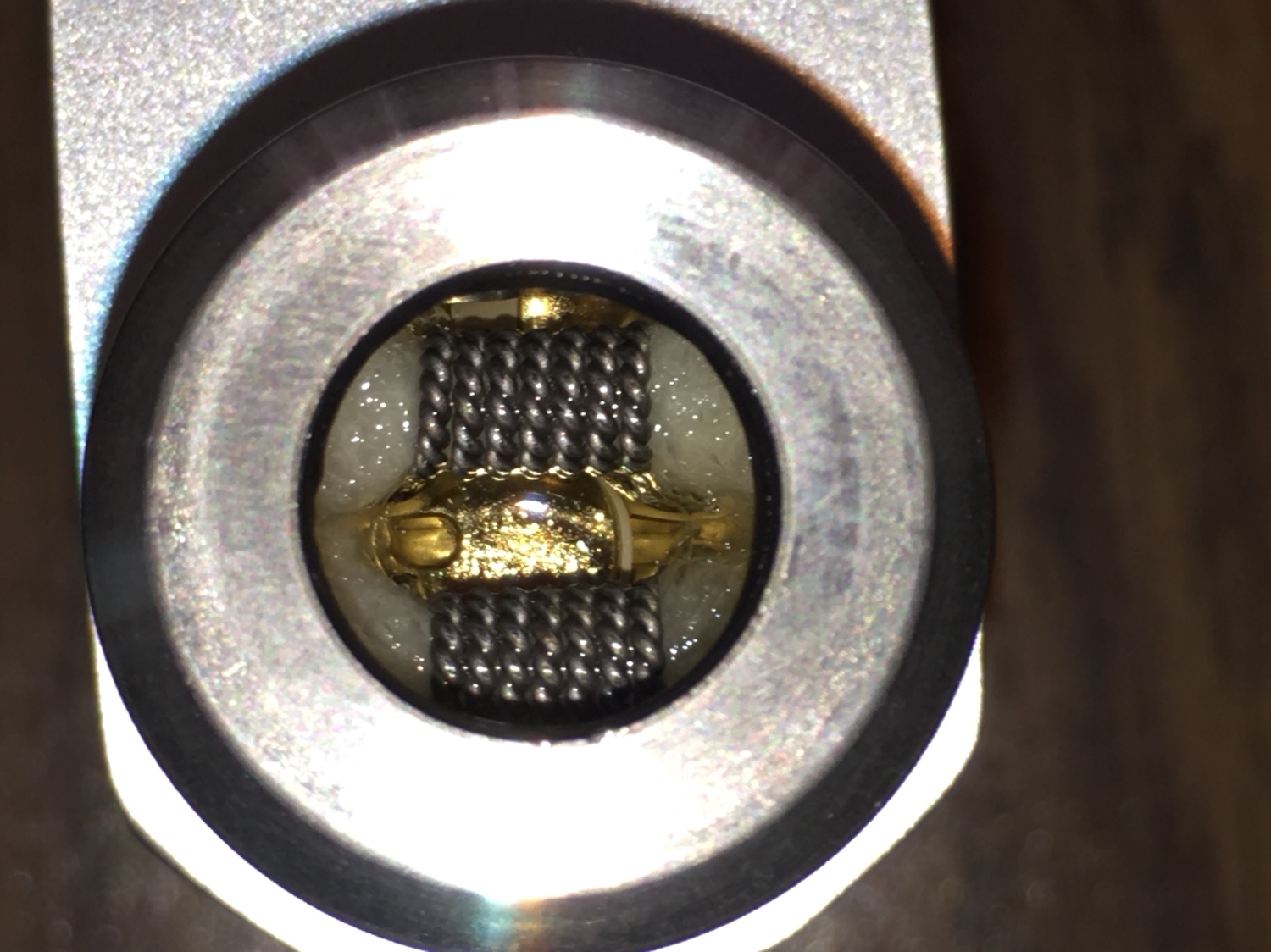

View attachment 96475

26ga framed staple twisted coil. (2x 26ga nicr twisted, 2x 26ga nicr, wrapped in 32ga) laptop cam isn't great for detail This build is 0.10 ohm. and takes a lot of wattage.

I know some members on here only build using SS wire. Both core and wraps. They say the flavor is better.

That is only their own personal preference. With a pair of fused claptons, for me, it is the other way around so, again........ different folks, different strokes I guess.

And I have NO IDEA what you are trying to say here. Since the stainless steel wrap does not carry a current and watts are an expression of electricity, not heat.

Wrong again. First off, especially in a simple clapton coil, the wrap wire does carry a little bit of current, albeit only just a little bit. With a fused clapton coil this effect becomes even much smaller still, but anyway... let's continue, shall we? Heat is a form of energy, which is expressed in Joules (or BTU or calories). Transferred heat is expressed in watts. Heat is transferred into the coil by means of an electric current, but if you want to transfer an equal amount of heat into the coil, then the watts need to be equal. The resulting temperature increase is defined by how many watts are applied to the coil for how many seconds, and is also defined by volumetric heat capacity because the size and shape of the coil needs to be equal if you want to do a fair comparison of two different metal types in terms of how fast the coil heats up ( =how fast their temperature is increased), for reasons that are obvious.

Now what you say does apply if we are talking about the core wire. But we never were talking about the core.

You were talking about coils that include a wrap wire. Therefore, it makes sense for me to conclude we are talking about coils that also include at least one core wire... which means we most definitely

ARE talking about the core wire. Now, heat is transferred from the cores into the wrap wire. This happens by means of thermal conduction in the area where the core touches the wrap wire, but this also happens via the juice that's sitting in the tiny crevasses between the core and wrap wire. Next, because Nichrome80 conducts heat slower [compared to SS316L wrap wire], the heat stays more concentrated at ( =slower moving away from) the area where the heat is coming from. Simply put, the heat that's entering the wrap wire spreads out slower inside the wrap wire. It means the heat stays more around the crevasses. As a result the heat moves faster into the juice that's inside those crevasses. And, in addition, the Nichrome80 wrap wire [of the same gauge] heats up faster due to Nichrome80 having a smaller volumetric heat capacity than SS316L (physics fact).

I use Nicr or kanthal usually for my core. Remember also, your wrap wire acts as a heat sink, so you are not only heating the core, you are actually heating the entire coil. NiCr wraps carry no current so are drawing heat from your core wire. SS draws heat faster, meaning the entire coil heats to vaping temperature faster.

Remember also, your juice acts as a heat sink. So you are not only heating the coil, you are actually heating the entire volume of juice that gets sucked up into the crevasses in the coil.

Lets look at PG.. boiling point is 370.8 degrees F. Now if we say that is the point you get vapor, it stands to reason that the faster your coil reaches that temperature, the faster you get vapor.

That's exactly my point. Nichrome80 heats up faster as well as heats up fastest in the part of it that is nearest to where most of the juice is anyway in the first place. So your point is not only moot, but double moot.

For all the catch phrases and buzz words you use, like Kalvin and volumetric heat transfer

Physics is a bitch, isn't it?

you miss the one main factor. BOTH cores being identical, the SS wrap transfers heat from the core to the ejuice faster, and neither coil will form a vapor until the entire coil has reached 370.8F.

Wrong again. Immediately as soon as all that juice inside those crevasses reaches boiling point, it starts to evaporate really fast so the trick is to get the heat to stay where those crevasses are, as that is where most of the juice is at.

This is why they make heat sinks for welding electronics from SS and NOT from Nichrome.

A juiced up coil is NOT a heat sink. Air does not get soaked up between the fins of a heat sink, but juice does get soaked up into the crevasses between the core wire and the wrap wire. Nice try!

This is why nearly every coil builder uses SS as a wrap.

LOL... lucky for me I'm not every coil builder!

Faster ramp up to vaping temperature and faster heat transfer from coil to ejuice.

LOL × 2

Your core wire and wrap wire heat up differently. One heats due to electrons passing through creating friction, the other heats passively by absorbing heat from the core wires.

Do you mean to tell me it doesn't absorb heat from the juice that sits between the core wires and the wrap wire? LOL × 3